Our Services: Lining Design

Drawing on decades of experience and rigorous research and development, we are well-equipped to design customized refractories for your plant.

Working with a global network of technical specialists, the first step in the design process is a site visit, to better understand your operational needs. Our team has a talent for maximizing refractory efficiency by identifying the key areas for improvement.

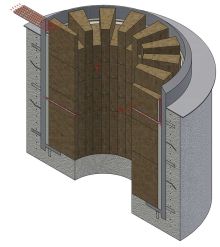

Once we have a solid understanding of your requirements, we can select the shape, size, structure, and composite of the bespoke refractories. We consider a range of key factors to produce a design that answers your objectives, from extending vessel life to reducing operating costs.

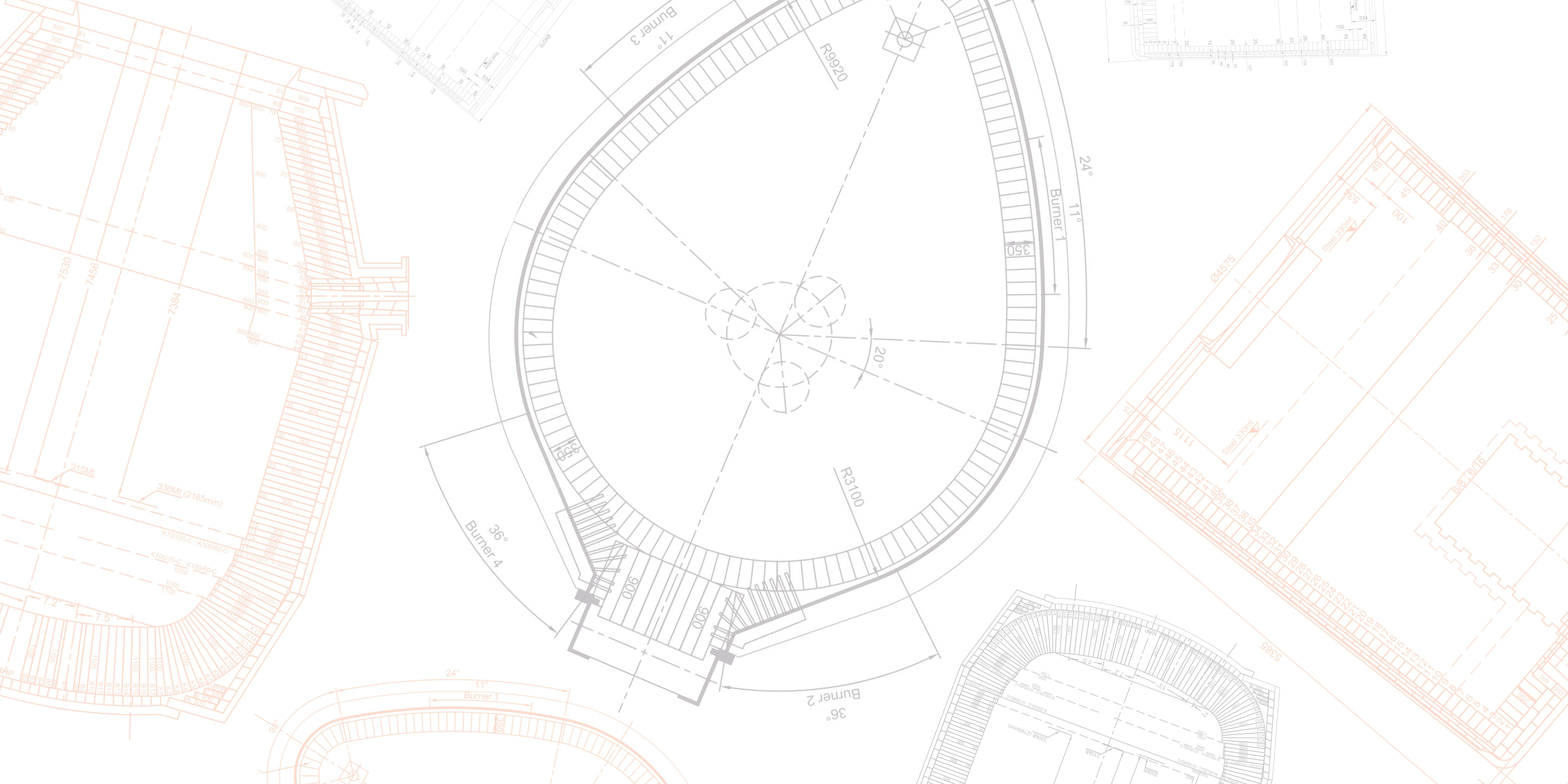

Using state-of-the-art CAD software, your new linings are drawn up in collaboration with our expert engineers. These computer-generated models offer insight into product specification and compatibility, helping you visualise the custom product as it would appear in real life.

Finally, we work with you to finetune the final design, modifying the vessel lining concepts to deliver expertly balanced configurations. Every aspect of the design is carefully considered to minimise maintenance and maximise efficiency.