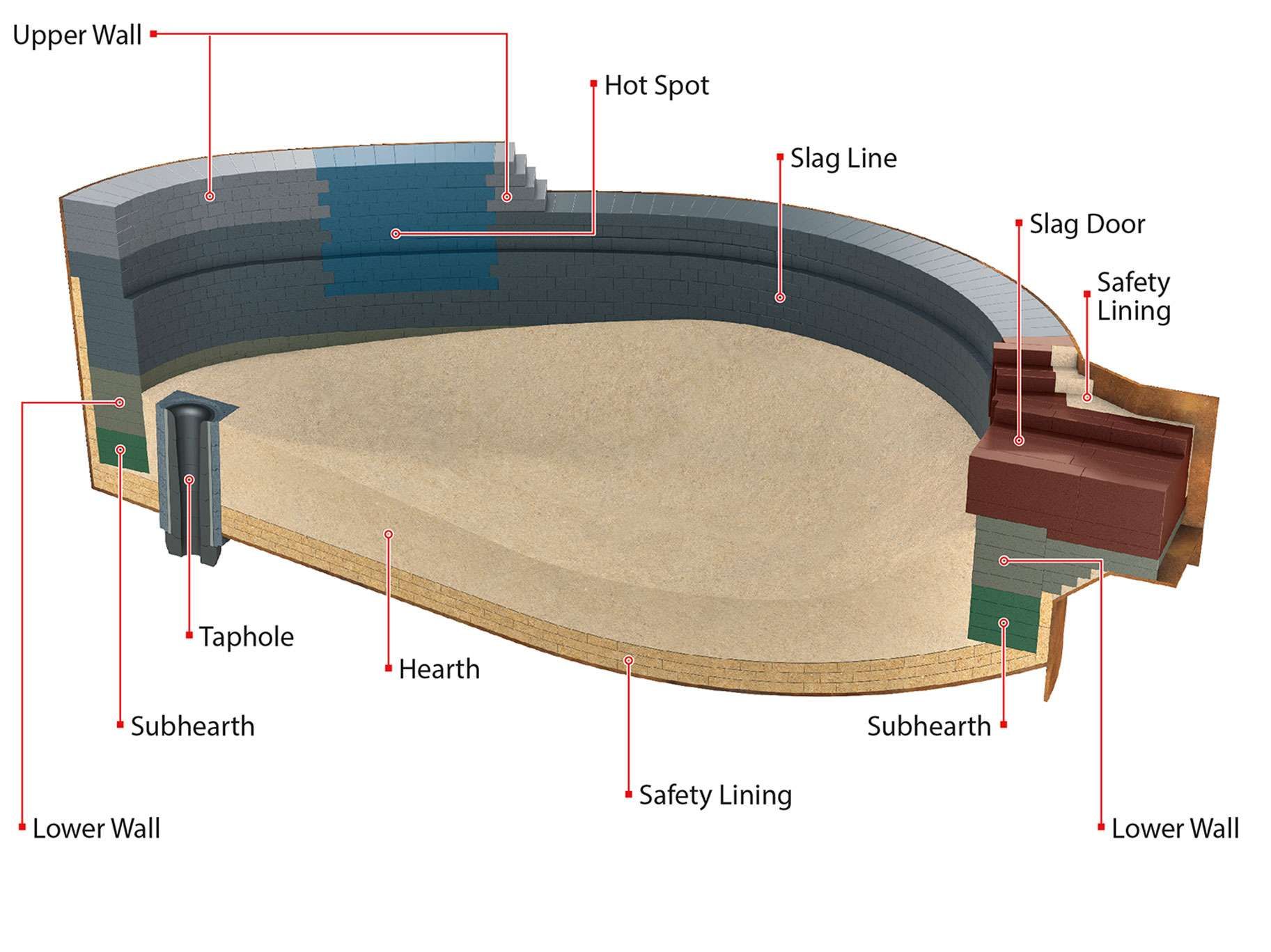

Applications: Electric ARC Furnace

Most electric arc furnaces worldwide are operated with alternating current.

In this process, the electric arc is generated in or above the steel bath using carbon electrodes that are introduced into the furnace through openings in the furnace lid. By contrast, DC arc furnaces conduct current from the electrode to a bottom anode.

For both types of furnaces, Mayerton supplies the required customized, high-quality products, from safety lining to unshaped products to sidewall bricks for the wear lining.

In addition to our focus on the production of the highest quality carbon-bonded shaped refractory products, we also supply our customers with unshaped materials such as hearth ramming mixes, fettling mixes, gunning mixes for hot and cold repairs, and various other repair and installation materials. The concepts are designed according to customer requirements and operational conditions.

Taphole (EBT – Eccentric Bottom Taphole)

We supply all the necessary components of tapholes required for controlled operation in the: Safety and working sleeves, end bricks and ramming mixes for filling the annular gap between safety and working sleeves. We supply both individual sleeves for self-assembly on site and interchangeable sets prefabricated in our manufacturing plant.

To manage the heavy wear caused by abrasion and oxidation, various refractory materials, such as fused magnesia, fused corundum, bauxite and silicon carbide, can be used. The taphole sets are manufactured according to customer requirements with a wide variety of internal contours.

Tapping Blocks and Spouts

We also have a wide range of products available for furnaces with tapping blocks in the side wall and corresponding spouts. These spouts are supplied to our customers as precast blocks made of high alumina castables or as pre-assembled blocks made of magnesia carbon bricks.

Hot Spot Areas

Since hot spot areas often limit the service life of the furnace, we use the highest-quality refractory materials based on high-purity magnesia and carbon raw materials. Depending on customer operating conditions, we select the magnesia raw material base, the carbon content, and potential antioxidant additions individually to optimize the performance of the entire furnace.

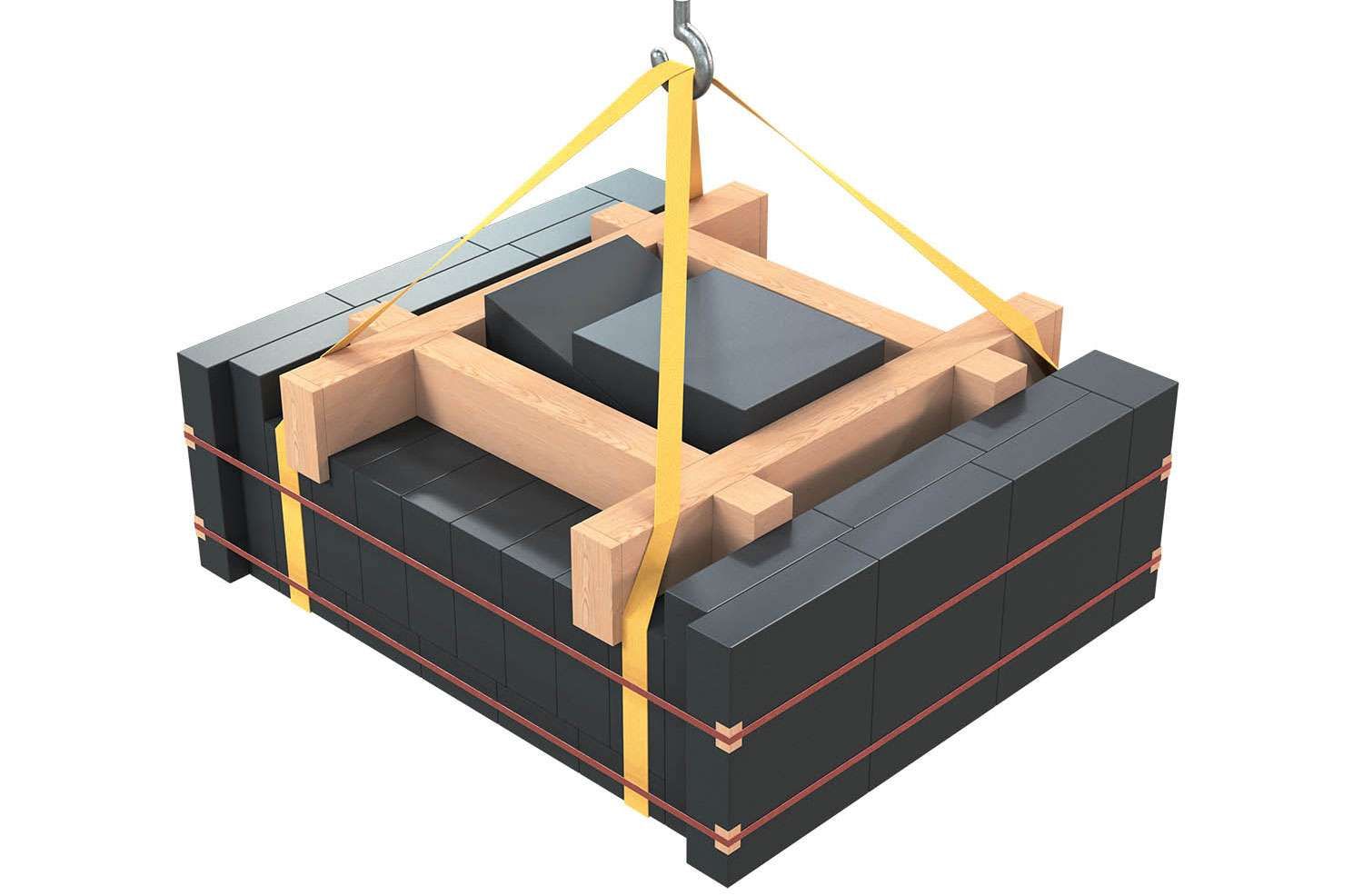

Slag Door

The slag door area is increasingly becoming a problem zone in electric arc furnaces. Constant exposure to slag, oxidizing conditions, and abrasive stress can lead to pre-wear of the refractory lining and limit the overall service life of the furnace. For this reason, Mayerton offers – besides the conventional delivery of single bricks – preassembled slag door blocks, which are installed as a single component into the furnace on-site. The precise pre-assembly and the materials used lead to significantly increased lifetimes.

Our designers not only design the slag door area but also take care of the appropriate lifting equipment in order to be able to lift the often very heavy block into the furnace safely and without danger.

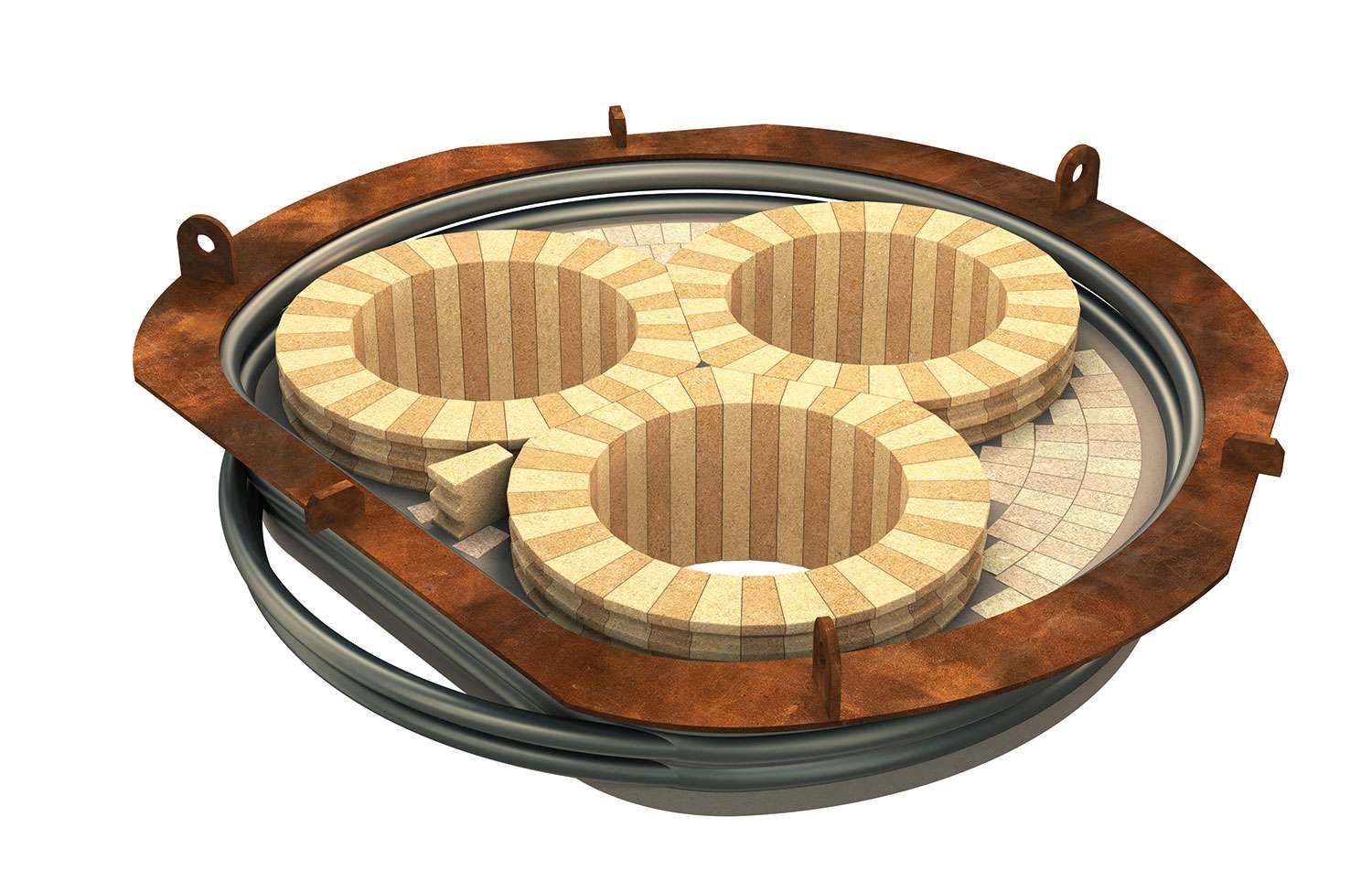

Bottom Purging Plugs in the Electric Arc Furnace

Mayerton supplies premium quality purging plugs for the melting down of the raw material scrap, DRI or HBI, and steel refining. Recent developments in the overall melting process demonstrate the increasing importance of gas purging in the EAF. Mayerton’s purging plugs allow the introduction of different gases (argon, nitrogen) in desired quantities at any time during the melting process.

The purging plugs are normally installed in surrounding bricks to enable them to be changed during furnace repairs. The annular gap between the surrounding block and the purging plug is filled with appropriate ramming mixes.

We optionally supply pre-cast and dried lid components; castable to cast lids on-site or with bricks and castable to brick lids directly.

Gunning Maintenance/Repair

Gunning mixes are often used to maintain the furnace in slag zone, the slag door, and the side wall.

Depending on the intended use, these mixes contain various binders that ensure that the mix gets optimum adhesion to the surface of the bricks. There are gunning mixes available with phosphatic, silicate and sulphate binders.

In the case of cold repairs with gunning mixes, the composition of the brick materials installed should be considered. Due to the risk of hydration, it is not advisable to maintain bricks containing antioxidants during cold repairs with gunning mix. The cooled brick structure absorbs water from the gunning mix and the aluminum carbide formed during operation is thus hydrated, resulting in brick disintegration.

Hearth Ramming and Fettling Mixes

For the arc furnace hearth lining, we offer products based on the sintered magnesia and sintered dolomite.

The chemistry and the grain size of the mixes are adjusted according to the operating conditions and the furnace conditions – for example, the inclination of the slope of the hearth. Additives for plasticizing the mass for steeper slopes and dust binding are available. A wide variety of tools are used for deaeration and compaction of the hearth masses. For these tools, please contact our technical sales staff.

We offer corresponding fettling materials for the hot repair of hearths, which have good sintering properties due to their chemical composition.